Ọdịnaya Alloy nke Chrome Moly Plate

Chrome moly plate n'okpuru ASTM A387 na akara ule nke nwere ihe dị iche iche alloy dị n'okpuru ebe a, akara akara eji eme ihe bụ Gr 11, 22, 5, 9 na 91.

Ewezuga 21L, 22L na 91, klaasị ọ bụla dị na klaasị abụọ nke ike tensile dị ka akọwara na tebụl chọrọ tensile.Akara 21L na 22L nwere naanị Klas 1, na Ọkwa 91 nwere naanị Class2.

| Ọkwa | Ọdịnaya Chromium aha, % | Ọdịnaya Molybdenum aha, % |

| 2 | 0,50 | 0,50 |

| 12 | 1.00 | 0,50 |

| 11 | 1.25 | 0,50 |

| 22,22 l | 2.25 | 1.00 |

| 21,21L | 3.00 | 1.00 |

| 5 | 5.00 | 0,50 |

| 9 | 9.00 | 1.00 |

| 91 | 9.00 | 1.00 |

Ụkpụrụ ezoro ezo maka ASTM A387 Alloy Steel Plate ASTM

A20/A20M: Ihe achọrọ maka efere arịa nrụgide.

A370: Nnwale nkọwapụta maka ihe eji arụ ọrụ igwe

A435/A435M: N'ihi na ogologo-beam ultrasonic nnyocha nke ígwè efere.

A577/A577M: N'ihi na ultrasonic angle beam nnyocha nke ígwè efere.

A578/A578M: N'ihi na ogologo beam UT ule nke akpọrepu ígwè efere na pụrụ iche ngwa.

A1017 / A1017M: Nkọwapụta maka arịa mgbali elu nke alloy steel, chromium-molybdenum-tungsten.

Nkọwapụta AWS

A5.5/A5.5M: Ala alloy ígwè electrodes maka ọta metal arc ịgbado ọkụ.

A5.23/A5.23M: Ala alloy ígwè electrodes maka fulxes maka submerged arc ịgbado ọkụ.

A5.28/A5.28M: Maka ịgbado ọkụ gas kpuchie ya.

A5.29/A5.29M: N'ihi na flux cored arc ịgbado ọkụ.

Ọgwụ ọkụ maka A387 Chrom Moly Alloy Steel Plate

Chrome moly alloy steel plate n'okpuru ASTM A387 ka a ga-egbu nchara, na-eji ọkụ na-ekpo ọkụ ma ọ bụ na-ekpochapụ, nhazi na iwe ọkụ.Ma ọ bụ bụrụ na onye na-azụ ahịa kwenye, ngwa ngwa jụrụ oyi site na austenitizing okpomọkụ site na mgbawa ikuku ma ọ bụ nkwụsị mmiri mmiri, na-esote iwe ọkụ, okpomọkụ kacha nta ga-adị ka tebụl n'okpuru:

| Ọkwa | Okpomọkụ, °F [°C] |

| 2, 12 na 11 | 1150 [620] |

| 22, 22L, 21, 21L na 9 | 1250 [675] |

| 5 | 1300 [705] |

Ọkwa 91 alloy ígwè efere ga-ekpo ọkụ na-emeso site normalizing na tempering ma ọ bụ site accelerated jụrụ site ikuku gbawara ma ọ bụ mmiri mmiri quenching, sochie tempering.Ọ dị mkpa ka e megharịa efere ọkwa 91 na 1900 ruo 1975°F [1040 ruo 1080°C] ma a ga-esunye ya na 1350 ruo 1470°F [730 ruo 800°C]

Ọkwa 5, 9, 21, 21L, 22, 22L, na efere 91 nyere iwu na-enweghị ọgwụgwọ okpomọkụ site na tebụl dị n'elu, a ga-agwụcha ma ọ bụrụ na ọ kwụsịrị ma ọ bụ ọnọdụ mgbakasị ahụ.

Nkọwa nkọwa

-

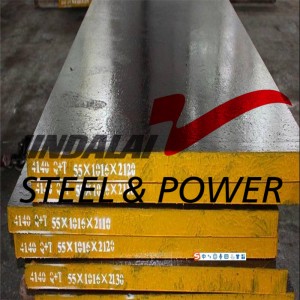

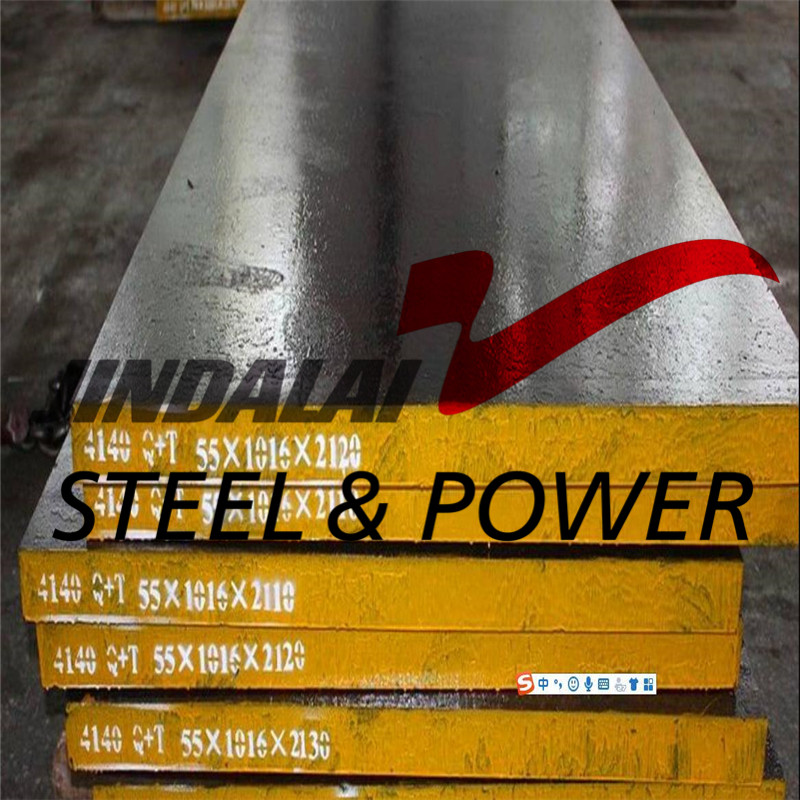

4140 Alloy Steel efere

-

Nickel Alloy Plate 200/201

-

Nickel Alloy Plates

-

ASTM A36 Steel Plate

-

Plate Steel Checkered

-

AR400 Steel efere

-

Abrasion eguzogide ígwè efere

-

Efere igwe ụgbọ mmiri nke 516 60

-

Igwe ọkụ igwe efere

-

Hardox Steel Plates China Supplier

-

Pipeline Steel efere

-

S235JR Carbon Steel Plate/MS Plate

-

Plate Structural Steel S355

-

Efere ígwè na-arụ ụgbọ mmiri

-

SA516 GR 70 Nrụgide Vessel ígwè efere

-

ST37 Steel efere / Carbon Steel efere