Nchịkọta

304 igwe anaghị agba nchara bụ ụdị eluigwe na ala igwe anaghị agba nchara, nchara na-eguzogide siri ike karịa 200 usoro igwe anaghị agba nchara, elu okpomọkụ na-eguzogide dịkwa mma, nwere ike ruo 1000-1200 degrees.304 igwe anaghị agba nchara nwere magburu onwe corrosion eguzogide na corrosion eguzogide n'etiti grains.N'ihi na oxidizing acid, na nnwale: ịta ≤365% nchara na-esighị ike acid okpomọkụ, corrosion resistance.Ọ nwekwara ezigbo corrosion eguzogide alkaline ngwọta na ọtụtụ organic na inorganic acid.

Nkọwapụta

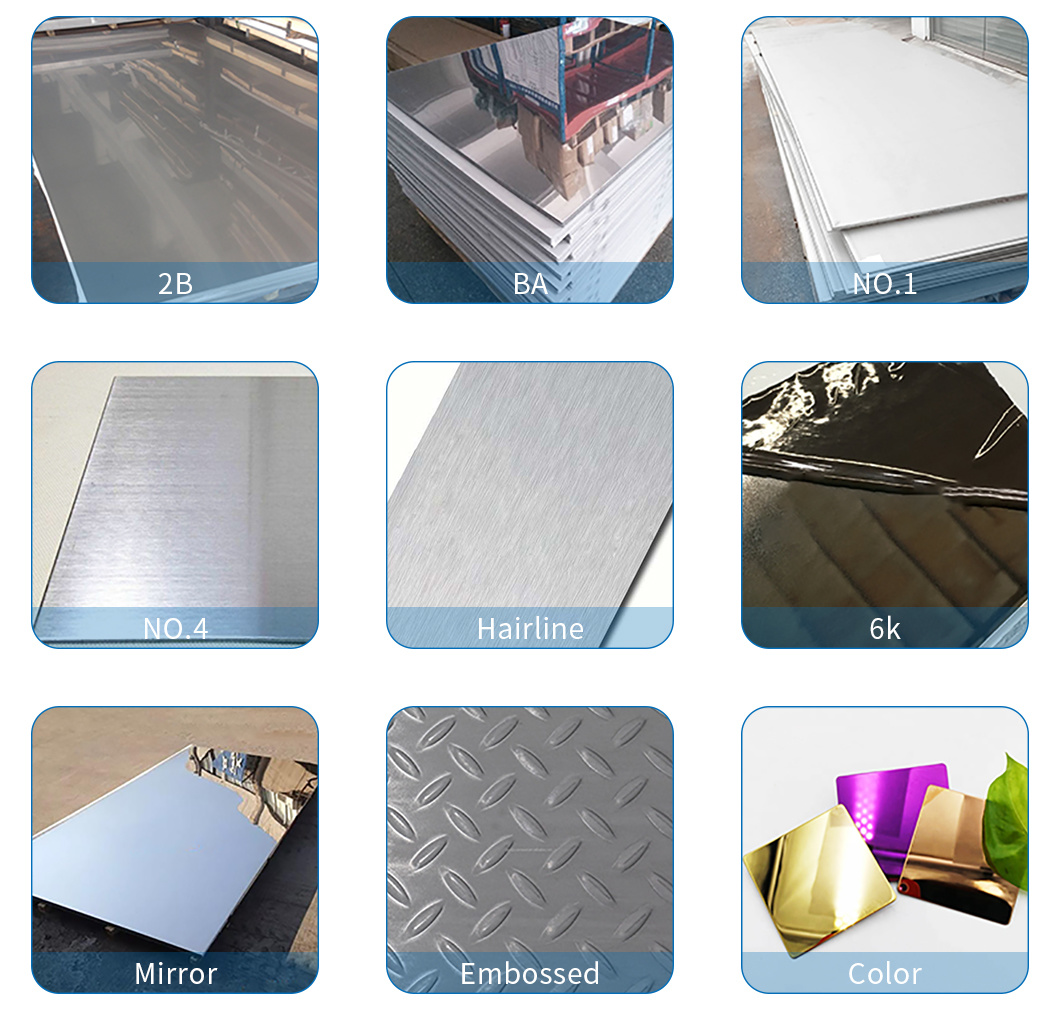

| Emecha elu elu | Nkọwa |

| 2B | Ngwunye na-egbuke egbuke, mgbe oyi gachara, site na ọgwụgwọ okpomọkụ, enwere ike iji ya mee ihe ozugbo, ma ọ bụ dị ka nzọụkwụ mbụ iji kpochapu. |

| 2D | Elu na-adịghị mma, nke na-esi na ntụgharị oyi na-esote site na mgbakasị ahụ na mwepu. Ọ nwere ike nweta akwụkwọ mpịakọta ọkụ ikpeazụ gafere na mpịakọta na-adịghị mma. |

| BA | Nchacha ọkụ na-egbuke egbuke nke a na-enweta site na ikpuchi ihe ndị dị n'okpuru ikuku ka ọnụ ọgụgụ ghara ịmepụta n'elu. |

| Mba.1 | Ọkpụkpụ siri ike, nke na-adịghị agwụ agwụ, nke na-esite na ntụgharị ọkụ na-ekpo ọkụ ruo n'ụdị akọwapụtara. Na-esochi ya site na mgbakasị ahụ na mbelata. |

| Nke 3 | Nke a imecha na-egbu maramara site No.100 ka No.120 abrasive kpọmkwem na JIS R6001. |

| Nọmba.4 | Nke a imecha na-egbu maramara site No.150 ka No.180 abrasive kpọmkwem na JIS R6001. |

| Ntutu isi | Ngwunye mara mma, nke ihe nkiri PVC na-echebe tupu eji ya eme ihe na kichin kichin, |

| Igwefoto 8K | "8" na 8K na-ezo aka n'oke nke ihe alloy (304 igwe anaghị agba nchara na-ezo aka na ọdịnaya nke ihe), "K" na-ezo aka na ọkwa nke reflectivity mgbe polishing. Igwe enyo 8K bụ ọkwa elu enyo gosipụtara site na chrome nickel alloy steel. |

| Embosed | Embossed igwe anaghị agba nchara bụ ihe dị iche iche eji eme ihe ịchọ mma n'elu igwe. Ha bụ nhọrọ magburu onwe ya maka ọrụ ụlọ, splashbacks, signage, na ndị ọzọ. Ha dị fechaa nke ukwuu, enwere ike ịkpụzi ha iji zute nkọwapụta nke ngwa dị iche iche dị iche iche. |

| Agba | Agba agba bụ titanium mkpuchi igwe anaghị agba nchara. A na-enweta agba ndị ahụ site na iji usoro mmepụta PVD. Ụdị dị n'elu mpempe akwụkwọ ọ bụla na-enye ụdị mkpuchi dị iche iche, dị ka oxides, nitrides na carbides. |

Ihe eji eme ihe bụ

1. Used maka nhazi ụdị akụkụ ọ bụla nke a na-ahụkarị na maka stamping anwụ;

2.Used dị ka elu nkenke n'ibu akụkụ nke ígwè;

3. A na-eji ya eme ihe n'ọtụtụ ebe na usoro ọgwụgwọ okpomọkụ nke nhụsianya annealing tupu ehulata.

4. Enwere ike iji ya mee ihe dị ka ihe eji arụ ụlọ maka iwu obodo.

7. Enwere ike iji ya na ụlọ ọrụ ụgbọ ala.

8. Enwere ike itinye ya na ụlọ ọrụ ngwa ụlọ. Ngalaba ike nuklia. Oghere na ụgbọ elu. Igwe eletriki na igwe eletrik. Ụlọ ọrụ igwe ọgwụ. Ụlọ ọrụ mmepụta ụgbọ mmiri.

Ngwakọta kemịkalụ nke igwe anaghị agba nchara a na-ejikarị

| Ọkwa | C | Si | Mn | P | S | Ni | Cr | Mo | Ndị ọzọ |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | - | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | - | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | - | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | - | N: 0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | - | N: 0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | - | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | - | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N: 0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N: 0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | - | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | - | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 mirror agba igwe anaghị agba nchara mpempe akwụkwọ na S...

-

Mpempe igwe anaghị agba nchara 316L 2B

-

304 Igwe anaghị agba nchara mpempe akwụkwọ etching efere

-

Mpempe igwe anaghị agba nchara 430

-

SUS304 Mpempe igwe anaghị agba nchara

-

201 J1 J3 J5 igwe anaghị agba nchara

-

Mpempe akwụkwọ igwe anaghị agba nchara

-

Mpempe igwe anaghị agba nchara PVD 316

-

SUS304 BA igwe anaghị agba nchara ọnụ ahịa kacha mma

-

SUS316 BA 2B igwe anaghị agba nchara na-ebubata