Bras

Ojiji nke ọla na ọla kọpa malitere na narị afọ gara aga, a na-ejikwa taa na ụfọdụ teknụzụ na ngwa kachasị ọhụrụ mgbe a ka na-eji ya eme ihe bụ ngwa ọdịnala dị ka ngwa egwu, eyelet brass, ihe ịchọ mma na mgbata na ngwa ngwa ụzọ.

Kedu ihe ejiri mee Brass?

Brass bụ ihe a na-eme site na ngwakọta ọla kọpa na zinc iji mepụta ihe ndị nwere ọtụtụ ọrụ injinia. Ngwakọta brass na-enye ígwè ahụ ebe mgbaze dabara adaba maka ọtụtụ ngwa, gụnyere adabara maka ịbanye na iji usoro brazing. Ebe mgbaze nke ọla dị ala karịa ọla kọpa na gburugburu 920 ~ 970 degrees Celsius dabere na ego mgbakwunye Zn. Ebe mgbaze ọla dị ala karịa nke ọla kọpa n'ihi Zn agbakwunyere. Alloys bras nwere ike ịdị iche na nhazi Zn site na obere ihe dịka 5% (nke a na-akpọkarị Gilding Metals) ruo ihe karịrị 40% dịka ejiri ya na brasses igwe. Okwu a na-ejikarị eme ihe bụ ọla kọpa, ebe a na-eji ihe mgbakwunye ụfọdụ nke tin mee ihe.

Kedu ihe a na-eji ọla kọpa?

Ngwakọta ọla na mgbakwunye nke zinc na ọla kọpa na-ebuli ike ma na-enye ụdị àgwà dị iche iche, nke na-eme ka brasses bụ ihe dị iche iche dị iche iche. A na-eji ha maka ike ha, nguzogide corrosion, ọdịdị na agba, na ịdị mfe nke ịrụ ọrụ na ịbanye. Otu akụkụ alfa brass, nwere ihe ruru 37% Zn, dị nnọọ ductile ma dị mfe ịrụ ọrụ oyi, weld na braze. A na-arụkarị brass alfa-beta nke abụọ na-ekpo ọkụ.

Enwere ihe karịrị otu ihe mejupụtara ọla?

Enwere ọtụtụ brasses nwere nhazi na njirimara dị iche iche ahaziri maka ngwa dị iche iche site na ọkwa nke mgbakwunye zinc. A na-akpọkarị ọkwa dị ala nke mgbakwunye Zn Guilding Metal ma ọ bụ Red Brass. Ebe ọkwa dị elu nke Zn bụ alloys dị ka Cartridge Brass, Brass Machining Free, Brass Naval. Bras ndị a na-esote nwekwara mgbakwunye nke ihe ndị ọzọ. A na-eji mgbakwunye nke ndu na ọla mee ihe ruo ọtụtụ afọ iji nyere aka n'ịrụ ọrụ nke ihe site n'ịkwalite isi nkwụsị mgbawa. Dika achọpụtala ihe ize ndụ na ihe egwu dị na ledu, n'oge na-adịbeghị anya, ejirila ihe ndị dị ka silicon na bismuth dochie anya iji nweta ụdị ngwa ọrụ ahụ. A maara ndị a ugbu a dị ka obere ndu ma ọ bụ ọla na-enweghị isi.

Enwere ike ịgbakwunye ihe ndị ọzọ?

Ee, enwere ike ịgbakwunye obere ihe ndị ọzọ na-eme ka ọ bụrụ ọla kọpa na ọla. Ihe atụ ndị a na-ahụkarị bụ ụzọ maka ike igwe dị ka ekwuru n'elu, kamakwa arsenic maka nguzogide corrosion na dezincification, tin maka ike na corrosion.

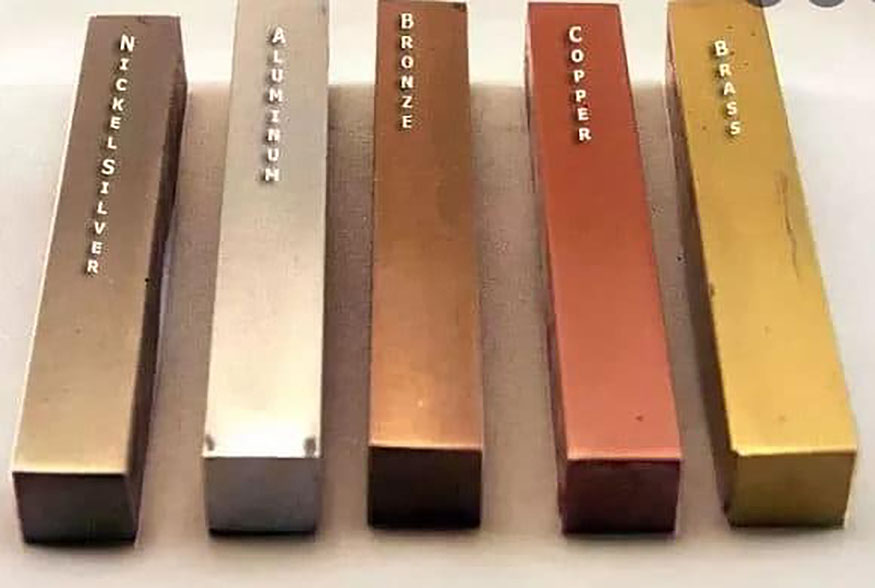

Agba Brass

Ka ọdịnaya zinc na-abawanye, agba na-agbanwe. Alloys Zn dị ala nwere ike ịdị ka ọla kọpa na agba, ebe nnukwu zinc alloys pụtara ọla edo ma ọ bụ odo.

Ngwakọta kemịkalụ

AS2738.2 -1984 Nkọwa ndị ọzọ dịka nhata

| UNS Mba | AS Mba | Aha nkịtị | Nọmba BSI | ISO No | JIS Mba | Ọla kọpa% | Zinc% | Ndu % | Ndị ọzọ% |

| C21000 | 210 | 95/5 Gilding metal | - | CuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding metal | CZ101 | CuZn10 | C2200 | 89.0-91.0 | ~ 10 | <0.05 | |

| C23000 | 230 | 85/15 Gilding metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | <0.05 | |

| C24000 | 240 | 80/20 Gilding metal | CZ103 | CuZn20 | C2400 | 78.5-81.5 | ~ 20 | <0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | <0.07 | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 Bras | CZ106 | CuZn30 | C2600 | 68.5-71.5 | ~ 30 | <0.05 | |

| C26800 | 268 | Ọla edo edo (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | <0.15 | |

| C27000 | 270 | 65/35 Waya Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | <0.10 | |

| C27200 | 272 | 63/37 Brass nkịtị | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | <0.07 | |

| C35600 | 356 | Brass ihe osise, 2% ndu | - | CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | Brass ihe osise, 1% ndu | - | CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Akụkụ Brass | CZ121 | CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | Aluminom 0.10-0.6 |

| C38500 | 385 | Ịcha ọla n'efu | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

A na-ejikarị brasses eme ihe maka ọdịdị ha

| UNS Mba | Aha nkịtị | Agba |

| C11000 | ETP ọla kọpa | Pink dị nro |

| C21000 | 95/5 Gilding metal | Agba aja aja |

| C22000 | 90/10 Gilding metal | ọla edo ọla |

| C23000 | 85/15 Gilding metal | Tan Gold |

| C26000 | 70/30 Bras | Green Gold |

Ịgba ígwè

C22000, 90/10 Gilding metal, na-ejikọta agba ọla edo bara ụba yana nchikota ike kachasị mma, ductility na nguzogide corrosion nke ala Cu-Zn alloys. Ọ na-adaba na agba ọla kọpa bara ụba. Ọ nwere ikike ịse ihe omimi dị oke mma, yana iguzogide corrosion na-emebi emebi na oke ihu igwe na gburugburu mmiri. A na-eji ya na fascias ụkpụrụ ụlọ, ihe ịchọ mma, ihe ịchọ mma, aka ọnụ ụzọ, escutcheons, ngwaike mmiri.

Ọla edo edo

C26000, 70/30 Brass na C26130, Arsenical brass, nwere ọmarịcha ductility na ike, yana ọla ndị a na-ejikarị eme ihe. Arsenical brass nwere obere mgbakwunye nke arsenic, nke na-eme ka nguzogide corrosion dị na mmiri dịkwuo mma, mana ọ bụ otu nke ọma. Alloys ndị a nwere agba odo na-egbukepụ egbukepụ nke jikọtara ya na ọla kọpa. Ha nwere nchikota kacha mma nke ike na ductility na Cu-Zn alloys, yana ezigbo nguzogide corrosion. A na-eji C26000 mee ihe maka ihe owuwu, ihe osise na ihe atụ, ọdụ eletrik na njikọ, aka ọnụ ụzọ, na ngwaike plumbers. A na-eji C26130 maka tube na ihe ntinye na kọntaktị na mmiri, gụnyere mmiri ọṅụṅụ.

C26800, ọla edo edo, bụ otu akụkụ alfa brass nwere ọdịnaya ọla kọpa kacha ala. A na-eji ya ebe ihe omimi ya dị omimi na ọnụ ala dị ala na-enye uru. Mgbe welded ahụ nke oge beta nwere ike ịmalite, na-ebelata ductility na nguzogide corrosion.

Brasses na ihe ndị ọzọ

C35600 na C37000, Brass na-ese ihe, bụ 60/40 alpha-beta brasses nwere ọkwa dị iche iche agbakwunyere iji nye njirimara igwe n'efu. A na-eji ha eme ihe n'ọtụtụ ebe maka efere na plaque a kanyere, ngwa ndị na-ewu ụlọ, ngwa. E kwesịghị iji ha mee ihe maka ọrụ acid-etched, nke a ga-eji brasses alfa otu nkeji mee ihe.

C38000, Brass ngalaba, bụ alfa/beta brass na-agbapụta ngwa ngwa nwere obere aluminom, nke na-enye agba ọla edo na-egbuke egbuke. Ndu ahụ na-enye njirimara ịkpụ n'efu. C38000 dị ka mkpanaka extruded, ọwa, flat na akụkụ, nke a na-ejikarị na ngwa ndị na-ewu ụlọ.

C38500, ịcha ọla, bụ ụdị ọla kọpa 60/40 na-emeziwanye nke ọma, nwere njirimara ịkpụ n'efu. Ọ na-eji na uka mmepụta nke bras components ebe kacha mmepụta na ogologo ngwá ọrụ ndụ chọrọ, na ebe ọ dịghị ọzọ oyi na-akpụ mgbe machining chọrọ.

Ndepụta Ngwaahịa Brass

● Ụdị ngwaahịa

● Ngwaahịa ndị a kpụrụ akpụ

● mkpanaka arụrụ arụ, ogwe & ngalaba

● Ịmepụta ngwaahịa na ihe arụrụ arụ

● Ọkụ na-enweghị ntụpọ maka ndị na-agbanwe ọkụ

● Ọkụ na-enweghị ntụpọ maka ntụ oyi & refrigeration

● Ọkụ na-enweghị ntụpọ maka ebumnuche injinia

● Waya maka ebumnuche injinia

● Waya maka ebumnuche eletrik

Jindalai Steel Group na-enye ngwaahịa ọla dị iche iche na nha na oke iji gboo mkpa ọrụ ọ bụla. Anyị na-anabatakwa ụkpụrụ, nha, ụdị na agba. Zipu ajụjụ gị, anyị ga-enwe obi ụtọ ịkpọtụrụ gị ọkachamara.

HỤTỤTỤ:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com Weebụsaịtị:www.jindalaisteel.com

Oge nzipu: Dec-19-2022