1. Nzọụkwụ Mbụ: Agbaze

A na-eme aluminom site na iji electrolysis na ọkwa ụlọ ọrụ na ndị na-agbapụta aluminom chọrọ ike dị ukwuu iji na-agba ọsọ nke ọma. Ndị na-agbapụta ọkụ na-anọkarị n'akụkụ ụlọ ọrụ ike ọkụ n'ihi ihe ha chọrọ maka ume. Mmụba ọ bụla na ọnụ ahịa ike, ma ọ bụ oke ike achọrọ iji nụchaa aluminom na ọkwa dị elu, na-abawanye ụgwọ nke mkpuchi aluminom. Tụkwasị na nke ahụ, aluminom nke gbazere na-ekewa ma na-aga ebe nchịkọta. Usoro a nwekwara nnukwu ike chọrọ, nke na-emetụta ọnụ ahịa ahịa aluminom.

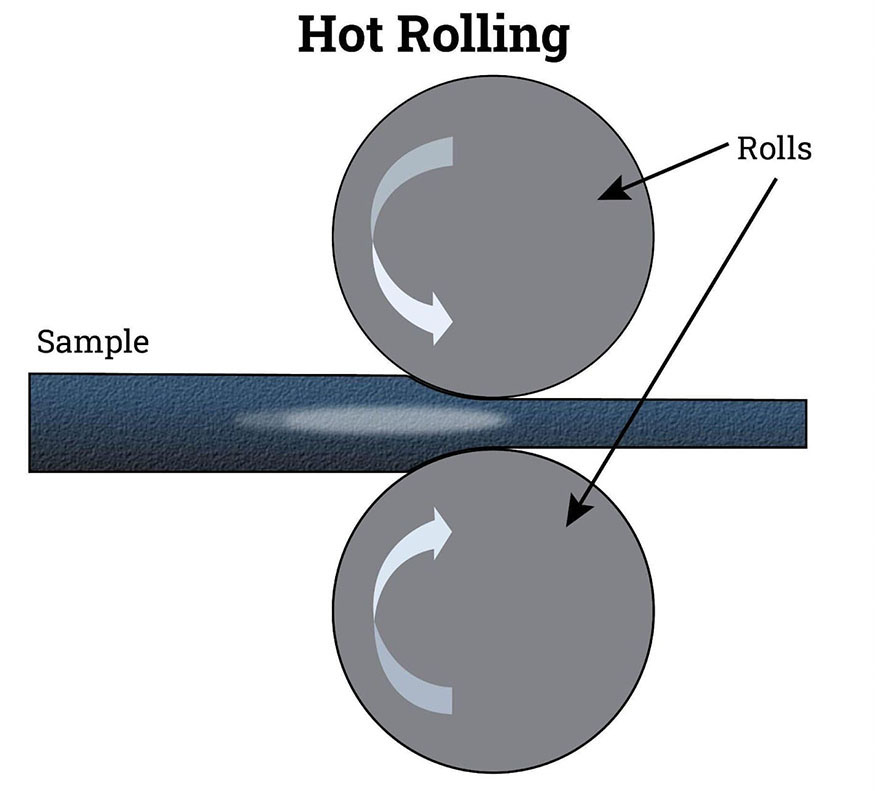

2. Nzọụkwụ abụọ: Hot Rolling

Mfegharị na-ekpo ọkụ bụ otu n'ime ụzọ a na-ejikarị eme ka slab aluminom dị mkpa. Na mpịakọta na-ekpo ọkụ, ígwè na-ekpo ọkụ n'elu ebe nke recrystallization iji mebie ma na-akpụzi ya ọzọ. Mgbe ahụ, a na-agafe ngwaahịa ọla a site na otu ma ọ bụ karịa ụzọ abụọ nke mpịakọta. A na-eme nke a iji belata ọkpụrụkpụ, mee ka ọkpụrụkpụ edo edo, yana iji nweta ogo igwe achọrọ. A na-emepụta eriri aluminom site na ịhazi mpempe akwụkwọ na 1700 degrees Fahrenheit.

Usoro a nwere ike ịmepụta ọdịdị na nha geometric kwesịrị ekwesị na njirimara ihe mgbe ị na-edebe olu ígwè ahụ mgbe niile. Ọrụ ndị a dị oke mkpa n'imepụta ihe emechachara na nke emechara, dị ka efere na mpempe akwụkwọ. Otú ọ dị, ngwaahịa ndị a kpụkọrọ akpụkọ dị iche na ihe mkpuchi oyi na-atụ, bụ́ nke a ga-akọwa n'okpuru ebe a, n'ihi na ha enwechaghị otu nha n'ihi obere irighiri ihe dị n'elu.

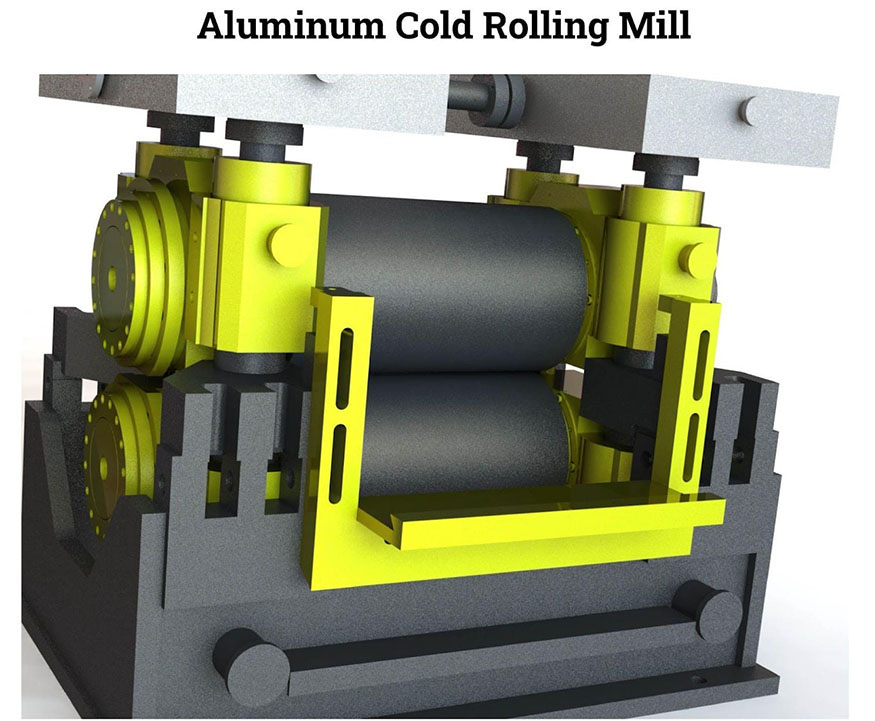

3. Nzọụkwụ atọ: Ntugharị oyi

Ntugharị oyi nke eriri igwe bụ mpaghara pụrụ iche nke ngalaba ọrụ igwe. Usoro nke "mgbagharị oyi" gụnyere itinye aluminum site na rollers na okpomọkụ dị ala karịa okpomọkụ recrystallisation. Ịpịpị na ịpịkọta ígwè ahụ na-abawanye ike mkpụrụ ya na isi ike. Ntugharị oyi na-apụta na okpomọkụ na-eme ka ọrụ sie ike (okpomọkụ dị n'okpuru ihe recrystallization okpomọkụ), na ntụgharị ọkụ na-apụta n'elu okpomọkụ na-eme ka ọrụ sie ike- nke a bụ ọdịiche dị n'etiti ntụgharị ọkụ na ntụgharị oyi.

Ọtụtụ ụlọ ọrụ na-eji usoro ọgwụgwọ igwe a maara dị ka mkpọgharị oyi na-emepụta warara na mpempe akwụkwọ nwere nlele ikpeazụ achọrọ. A na-ekpokọta mpịakọta ndị ahụ ugboro ugboro iji nyere aka na aluminom na-arụ ọrụ nke ọma, a na-ejikwa mmanu mee ihe iji gbochie eriri aluminom ịrapara na mpịakọta. Maka ịrụ ọrụ mma ntughari, enwere ike ịgbanwe mmegharị na okpomọkụ nke mpịakọta. Aluminom warara, nke emelarị ịgbagharị ọkụ na-ekpo ọkụ, na usoro ndị ọzọ, gụnyere ihicha na ọgwụgwọ, na-eme ka ọ dị jụụ n'ime ụlọ tupu etinye ya n'ahịrị igwe igwe oyi na ụlọ ọrụ aluminum. A na-ehicha aluminom site na ịsacha ya na ncha na ọgwụgwọ a na-eme ka eriri aluminom sie ike nke ọma iji gbochie ntụgharị oyi.

Mgbe edozichara usoro nkwado ndị a, ibe ahụ na-agafe ugboro ugboro site na rollers, na-eji nwayọọ nwayọọ na-efunahụ ọkpụrụkpụ. A na-akụghasị ụgbọ elu lattice nke ígwè ahụ ma kwụsịchaa ya n'oge usoro ahụ niile, nke na-ebute ngwaahịa ikpeazụ siri ike na nke siri ike. Ntugharị oyi bụ otu n'ime ụzọ kachasị ewu ewu maka ime ka aluminom sie ike n'ihi na ọ na-ebelata ọkpụrụkpụ nke aluminom ka a na-egwepịa ya ma na-ebugharị ya na rollers. Usoro ntụgharị oyi nwere ike wedata ọkpụrụkpụ eriri aluminom ruo 0.15 mm.

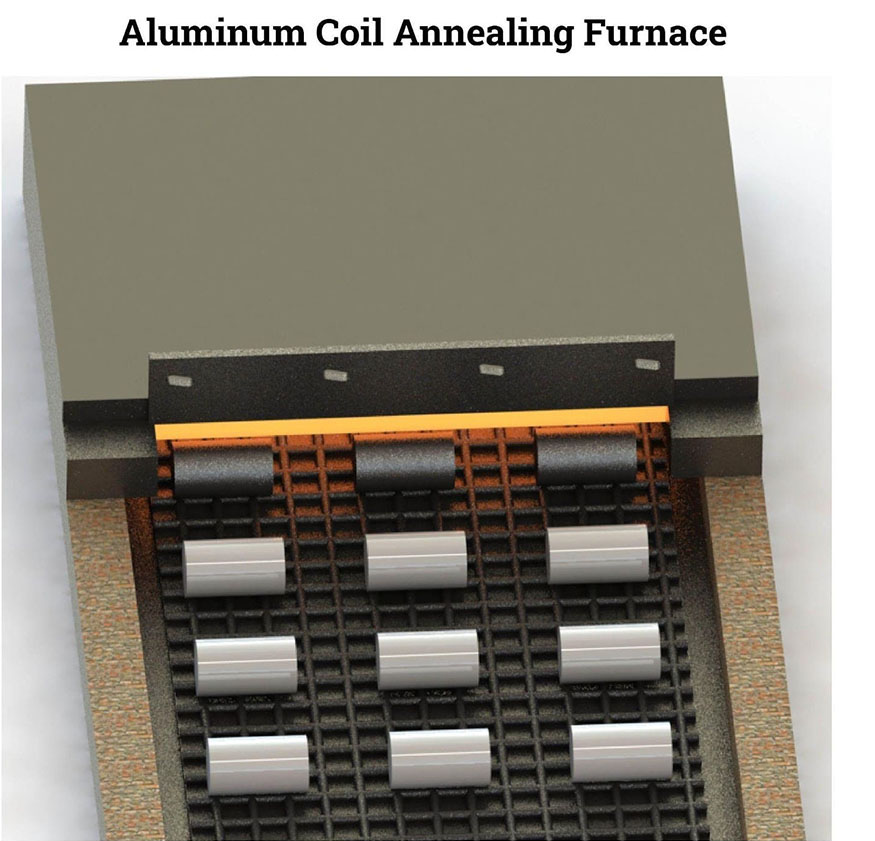

4. Nzọụkwụ anọ: Annealing

Usoro mgbakasị ahụ bụ ọgwụgwọ okpomọkụ a na-ejikarị eme ka ihe na-esiwanye ike ma ghara isi ike. Mbelata nkwụsịtụ na nhazi kristal nke ihe a na-ekpochapụ na-akpata mgbanwe a na ike na mgbanwe. Iji zere ọdịda na-adịghị emebi emebi ma ọ bụ iji mee ka ihe dị mma rụọ ọrụ maka ịrụ ọrụ na-eso ya, a na-eme ya ugboro ugboro mgbe ihe na-arụ ọrụ siri ike ma ọ bụ oyi.

Site n'ịtọgharịa usoro ọka kristal nke ọma, annealing na-eweghachi ụgbọ elu na-amị amị ma na-enye aka n'ịkpụzi akụkụ ahụ na-enweghị oke ike. Aluminom alloy arụ ọrụ siri ike ga-ekpo ọkụ n'otu ọnọdụ okpomọkụ dị n'etiti 570°F na 770°F maka oge a kara aka, site na ihe dị ka nkeji iri atọ ruo awa atọ. Ogo nke akụkụ a na-ekpochapụ na alloy a na-eme ya bụ ikpebi ọnọdụ okpomọkụ na oge achọrọ, n'otu n'otu.

Mkpuchi ahụ na-emekwa ka akụkụ akụkụ ahụ kwụsie ike, na-ewepụ nsogbu ndị nsogbu dị n'ime na-ebute, ma na-ebelata nrụgide dị n'ime nke nwere ike ibilite, n'otu akụkụ, n'oge usoro dị ka ịgha oyi ma ọ bụ nkedo. Na mgbakwunye, aluminom alloys ndị na-adịghị ekpo ọkụ nwekwara ike ịsachapụ nke ọma. Ya mere, a na-etinye ya ugboro ugboro na nkedo, extruded, ma ọ bụ aluminom akpara akpa.

A na-akwalite ikike imepụta ihe site n'ichicha ya. Ịpị ma ọ bụ na-ehulata siri ike, ihe ndị na-agbaji agbaji nwere ike bụrụ ihe ịma aka n'emeghị ka mgbaji. Ọkụ na-enye aka n'iwepụ ihe egwu a. Ọzọkwa, annealing nwere ike ịbawanye machinability. Oke mgbakasị nke ihe nwere ike bute iyi oke ngwá ọrụ. Site na nchichi, enwere ike ibelata ike ihe onwunwe, nke nwere ike ibelata ịdị arọ ngwá ọrụ. A na-ewepụ esemokwu ọ bụla fọdụrụ site n'iwepụ ya. Ọ na-akacha mma ibelata esemokwu ndị fọdụrụ ebe ọ bụla enwere ike n'ihi na ha nwere ike ibute mgbawa na nsogbu ndị ọzọ na-arụ ọrụ.

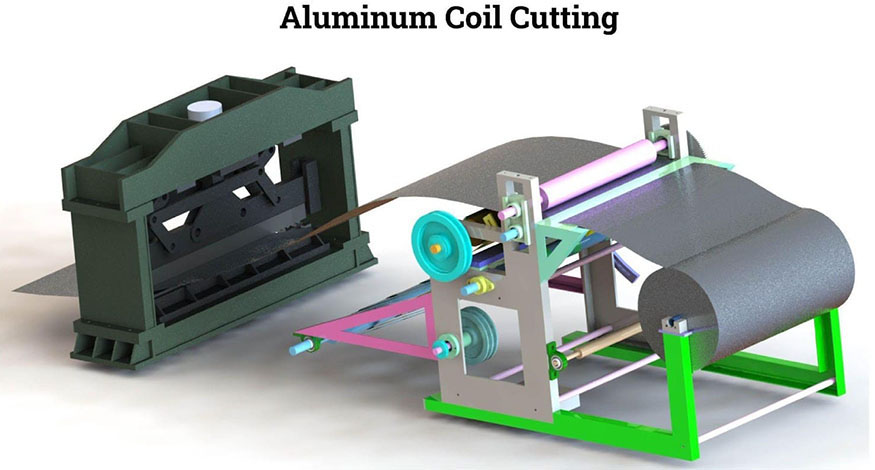

5. Nzọụkwụ ise: Ịcha na ịkpụ

Enwere ike rụpụta eriri igwe aluminom n'otu mpịakọta ogologo na-aga n'ihu. Iji wụnye eriri igwe n'ime mpịakọta ndị dị nta, agbanyeghị, ọ dị mkpa ka a kụrie ha. Iji rụọ ọrụ a, a na-eji aluminom na-apụta site na ngwa slitting ebe agụba dị nkọ na-eme nke ọma. A chọrọ ike dị ukwuu iji rụọ ọrụ a. Slitters na-ekewa akwụkwọ mpịakọta ahụ n'ime obere iberibe mgbe ike etinyere ya karịrị ike aluminom.

Iji malite usoro nkewa ahụ, a na-etinye aluminum n'ime ihe mkpuchi. E mechaa, a na-esi n'otu mma na-agbagharị agbagharị gafee ya. A na-edobe agụba ndị ahụ iji nweta ihu mgbawa kacha mma, na-atụle obosara na mkpochapụ achọrọ. Iji duzie ihe ndị gbawara agbawa na recoiler, a na-emesịa nye ya nri site na ndị na-ekesa ihe. A na-ejikọta aluminom ma kechie ya na eriri igwe iji kwadebe maka mbupu.

Jindalai Steel Group bụ ụlọ ọrụ Aluminom na-eduga na onye na-eweta ihe mkpuchi aluminom / mpempe akwụkwọ / efere / eriri / ọkpọkọ / foil. Anyị nwere ndị ahịa si Philippines, Thane, Mexico, Turkey, Pakistan, Oman, Israel, Egypt, Arab, Vietnam, Myanmar, India wdg Ziga ajụjụ gị na anyị ga-enwe obi ụtọ ịkpọ gị ọkachamara.

HỤTỤTỤ:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com Weebụsaịtị:www.jindalaisteel.com

Oge nzipu: Dec-19-2022